In the race to net zero, Aston Martin is determined to stay ahead of the curve. There are, however, no shortcuts in this challenging journey, a fact acknowledged by the team working in Aston Martin’s design studio in Gaydon.

“We’re not trying to eat the elephant in one go,” says Leighanne Earley, Creative Director of Interiors at Aston Martin. “Because if you try to do everything at once, you won’t win.”

This measured approach sets the tone for the Design Studio’s sustainability ambitions, shared by Leighanne and the rest of her team, who constantly look for ways to incorporate sustainable materials into Aston Martin’s products.

“We’re looking at how we can elevate the ordinary. How can we take a widely used material to the next level and put it in the ultra-luxury segment?” explains Jack Brown, Head of Colours, Materials and Finishes at Aston Martin. “But what we’re doing is meaningful and it has substance, so when we say we’re going to do something, we actually deliver on that.”

Consider leather, a contentious material in the current debate around sustainability. The team at Aston Martin’s Design Studio have opted for thoughtfulness over knee-jerk reactions.

“There’s been a lot of noise around leather and the fact it may not be sustainable, but a lot of that has been greenwashing,” says Jack. “Many companies have been quick to jump on the bandwagon and actually what they’re doing as an alternative is even worse because they’re using petroleum-based materials.”

Aston Martin proudly collaborates exclusively with Bridge of Weir, a family-owned Scottish business synonymous with comfort and timeless quality and renowned for producing the world’s lowest carbon-intensity leather. Measured at 1.1kg of CO2 per hide, Bridge of Weir’s leather is a by-product of beef cattle to ensure there is no waste or dedicated loss of animal life specifically for its production.

It is also a suitable partner for Aston Martin’s cradle-to-grave approach to sustainable sourcing, as Jack points out: “Looking at the whole supply chain, Bridge of Weir sources British hides locally – which are 100 per cent traceable – produces the leather in Scotland, and then we’re just down the road.”

Aston Martin’s commitment to Bridge of Weir’s responsible leather doesn’t preclude offering alternatives, however. Leading the way is Alcantara, a material closely resembling genuine leather and suede. “It offers a choice, which as a luxury brand is really important to us,” says Jack. “It’s lightweight and because it’s a fabric, you get really good cutting efficiency and therefore minimal waste. We are also looking at a recycled version of the material which we currently have in testing.”

Other leather alternatives on Aston Martin’s radar include Bananatex®, the world’s first durable, technical fabric made purely from naturally grown Abacá banana plants, and DeserttexTM, an upholstery derived from cacti. Both materials have been championed by the likes of Hermès and Stella McCartney.

Aston Martin is also taking its partnership with Bridge of Weir one step further by working with the manufacturer on a lighter-weight leather to reduce the weight of its cars.

“The great thing about sustainability and sportscars is the fact that we have to be lightweight,” says Leighanne. “The more weight we take out of the car, the better the performance, but it’s also great for sustainability. It goes hand-in-hand.”

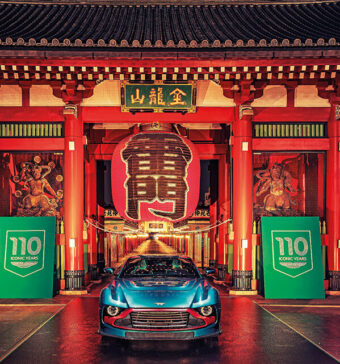

So how does this feed into Vantage, the latest model from Aston Martin’s next generation of sportscars?

Jack explains that the emphasis is unequivocably on the lightweight. “We’ve been using Alcantara much more in the car because it’s lighter. There’s a much more expansive use of carbon fibre – again because it’s lighter. There’s more we can do with Vantage as we move forward but we’re on a journey. Performance is driving our innovation and sustainability. That’s probably what differentiates us from every other brand: performance is the driver for us to achieve technical gains and sustainability at the same time.”

But it’s not just the product that Aston Martin designers view through an increasingly sustainable lens. The process is just as important. The development of 3D printing, for instance, has not only been game-changing for car components but also creative processes. “3D printing is wonderful in its capability and tooling and the fact that it is created digitally with no transit involved,” explains Leighanne. “Plus, every time the team use 3D printing, the resin gets ground down and all the waste gets reused back into the cartridges. That’s why 3D printing is so special.”

In addition, Aston Martin is revisiting its clay modelling process, and recycling the vital material involved. “This is a massive part of our journey in not creating waste in the studio because these cars are very big and we are shifting all the time,” explains Leighanne.

Recycled materials that will undoubtedly prove incredibly desirable for customers will be those derived from the Aston Martin AMR23, as driven by Fernando Alonso and Lance Stroll in the 2023 Formula 1® season.

Leighanne explains that they will take the parts of the race car, grind them down and use them in the brand’s Q by Aston Martin Bespoke programmes. “We don’t want it to be mainstream – you want to have the certificate, the traceability of each part. It becomes this whole special journey for that customer.”

Beyond the walls of the design studio, Aston Martin’s dealerships represent another important area for improved sustainability, building on the company’s recent carbon neutral manufacturing progress.

“There is a massive opportunity to reach a zero carbon footprint in our dealership network,” says Leighanne. “We’re looking at 100 per cent recycled stone, clay plaster and reclaimed timber, which we’re also looking at for our cars. Stuff that is brilliant and looks beautiful and has an elegance to it. My dream is that we start delivering fully zero carbon footprint dealerships with wind turbines, bringing greenery into the roof and recycled tyres as asphalt.”

Ultimately, one of the greatest sustainability stories Aston Martin has to tell is that a staggering 95 per cent of all Aston Martins ever made are still in existence. “We’re creating heirlooms that aren’t waste products. So that’s one of the things that we have to remind ourselves, that these cars are going to be handed down to future generations,” says Leighanne. “But that doesn’t mean we can be lazy. It doesn’t mean that we can’t drive and push materials.”